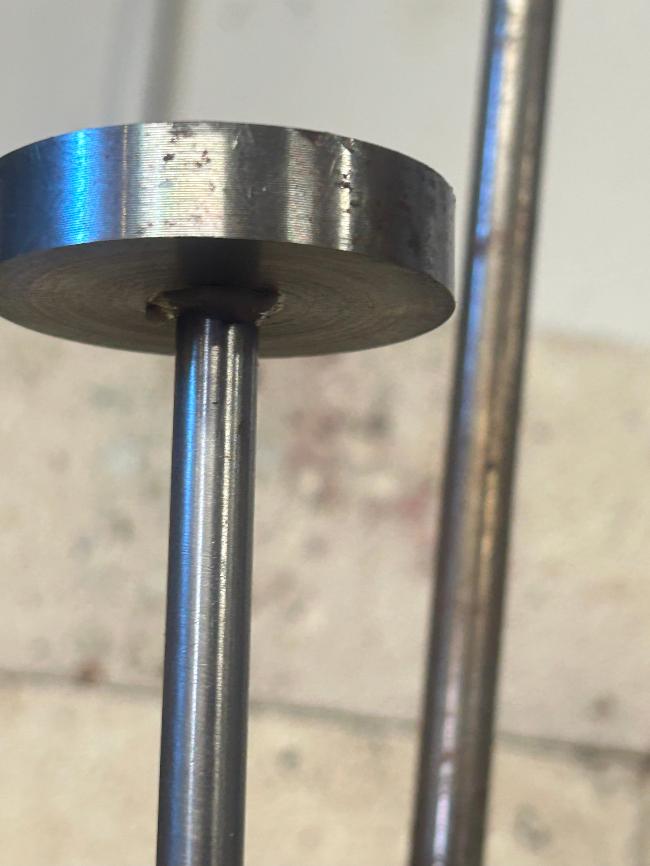

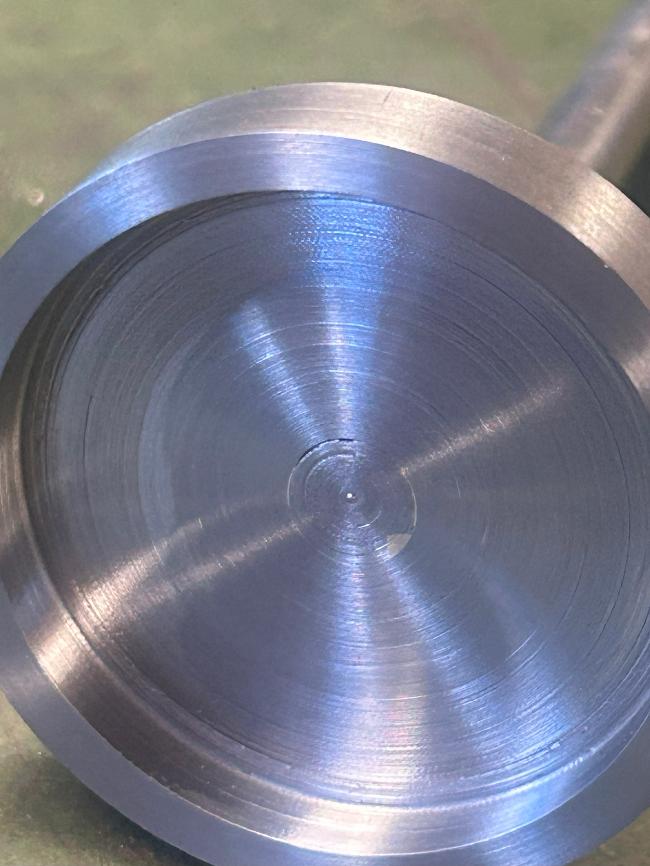

These could have been machined from solid bar but would have been very wasteful. So opted for a two piece fabrication, silver soldered together. The fabricated pistons and rods are left oversized so they can be machined to dimensions after silver soldering, to make sure everything ends up true and concentric.

The two pieces were threaded M8 for added strength and then soldered. To ensure the solder on a joint like this can flow freely through the joint and around the threads, I like to plane a groove along the thread to aid good penetration through the joint. The threads are also not tightened as the solder relies on a gap for the capillary action for the solder to flow. Below the photo shows chamfer tool turned on its side ready to cut grove.